Thermal Barriers

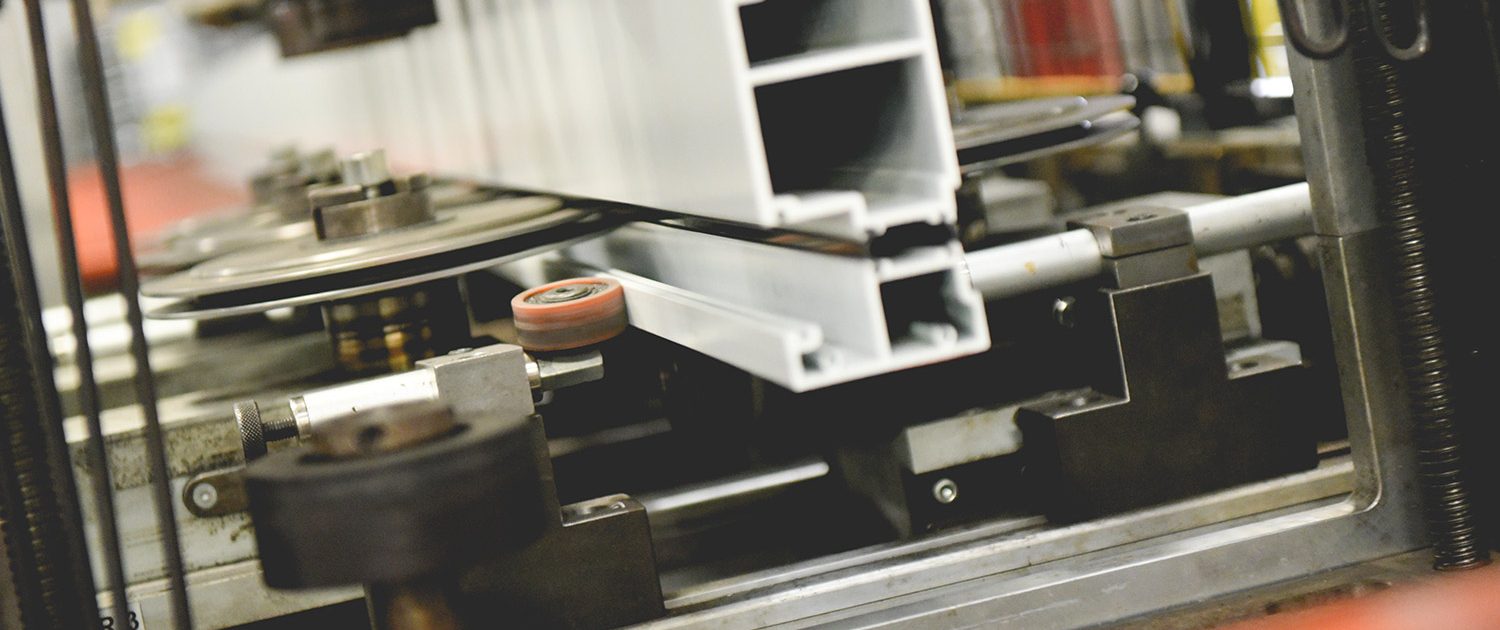

Thermal barrier strips are highly sought after energy conservation systems. Manufacturers seeking to increase LEED performance and U-value characteristics approach thermal barriers as a tool to combat ever-stricter government regulations and emphasis on smaller carbon footprints.

Thermal barriers decrease heat loss or heat gain and, when combined with aluminum, create a corrosion resistant, non-combustible, robust and durable system.